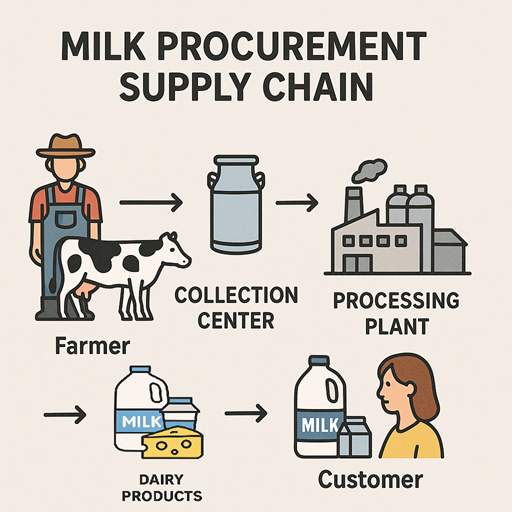

The Varanasi Milk Union has established a highly organized and disciplined milk procurement supply chain to ensure the smooth and

efficient collection of fresh milk from rural areas.

The Union operates over 50 rural milk procurement routes, each following a regular, pre-defined route plan. These plans are

meticulously designed with specific timings to pick up milk from every Dairy Cooperative Society (DCS) or village, both in the

morning and evening. Farmers are required to pour their milk into collection cans before the milk collection vehicle arrives at

their respective DCS.

Once all farmers at a DCS have poured their milk, it is consolidated into cans and prepared for pickup. At the scheduled time, the

milk collection vehicle arrives to load the cans and proceeds along its route, collecting milk from all the DCSs assigned to that

route.

After the completion of the collection route, the milk procurement vehicle transports the milk to the nearest Milk Chilling Center

(CC) or Bulk Milk Coolers (BMCs). Upon arrival at the CC/BMC:

- ⮚ Organoleptic tests (tests based on sensory evaluation like smell, appearance, and taste) are immediately conducted to assess the basic quality of milk.

- ⮚ The milk is weighed to verify the quantity received.

- ⮚ Samples are collected for more detailed laboratory testing, checking additional quality parameters beyond Fat and SNF, such as acidity, temperature, and bacterial load.

Following these initial checks, the milk is pumped into the chilling unit to rapidly lower its temperature, preserving its freshness and quality. After all vehicles complete their milk deliveries for the day, and all milk samples have been collected and tested, a comprehensive quality assessment is performed to ensure the entire batch at the Chilling Center meets the Union's strict quality standards. Once the milk at the Chilling Center is confirmed to be of acceptable quality :

- ⮚ It is loaded into insulated milk tankers and transported to the Varanasi Milk Union's dairy plant.

- ⮚ Upon arrival at the dairy plant, the milk undergoes another round of rigorous quality testing before being accepted for further processing into various dairy products.